Polyurethane Insulation Panels: Efficiency, Versatility, and Performance in Modern Construction

Posted in CategoryGeneral Discussion Posted in CategoryGeneral Discussion-

David Nlom 9 months ago

In today's construction and manufacturing landscape, thermal efficiency is more important than ever. With rising energy costs and increasing environmental regulations, the demand for high-performance insulating materials has grown rapidly. One solution that has gained widespread popularity for its exceptional thermal resistance, durability, and versatility is polyurethane insulation panels.

Used across residential, commercial, industrial, and transportation applications, polyurethane insulation panels have established themselves as a go-to choice for achieving long-term energy savings and superior climate control. This article explores what these panels are, how they’re made, their key advantages, common uses, and why they continue to shape the future of insulation technology.

What Are Polyurethane Insulation Panels?

Polyurethane insulation panels are rigid foam panels used to insulate walls, roofs, floors, and a variety of enclosures. They are made from polyurethane, a type of polymer formed through the chemical reaction of polyol and diisocyanate. When expanded, this foam creates a closed-cell structure that provides superior insulation properties compared to many other materials.

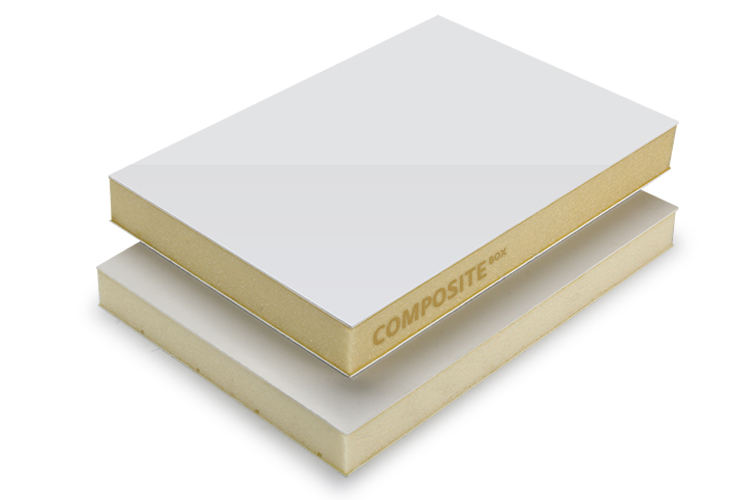

Typically, these panels consist of a core of polyurethane foam sandwiched between two outer skins—usually made of materials like aluminum foil, steel, fiberglass-reinforced plastic (FRP), or other durable facings. The outer skins add structural strength, protection, and resistance to moisture and mechanical damage.

How Are Polyurethane Insulation Panels Made?

The manufacturing process of polyurethane insulation panels involves several key stages:

-

Foam Formulation: The polyol and diisocyanate components are mixed, often with a blowing agent that causes the mixture to expand into a rigid foam.

-

Panel Assembly: The foam is injected or sprayed between two rigid facing materials. The chemical reaction expands the foam, filling the cavity and bonding tightly to the facings.

-

Curing: The panel is allowed to cure under controlled conditions. This ensures that the foam fully expands and achieves its maximum insulation and structural properties.

-

Cutting and Finishing: Once cured, the panels are trimmed, shaped, and sometimes coated for additional protection or customization.

This sandwich panel construction allows polyurethane panels to be both thermally efficient and structurally sound, making them useful in various demanding environments.

Key Advantages of Polyurethane Insulation Panels

1. Exceptional Thermal Performance

Polyurethane foam has one of the highest R-values per inch of any commercially available insulation material. This means it provides excellent thermal resistance with less material thickness. For example, a typical polyurethane panel offers an R-value of around 6 to 7 per inch—far higher than fiberglass or polystyrene alternatives.

This makes polyurethane insulation panels ideal for space-constrained areas or applications requiring maximum energy efficiency.

2. Lightweight Yet Strong

Despite their strength and rigidity, polyurethane panels are relatively lightweight. This makes them easy to transport, handle, and install, especially in prefabricated or modular construction. The outer skins further enhance the panel’s structural integrity, making them suitable for load-bearing wall and roof applications.

3. Moisture and Vapor Resistance

The closed-cell structure of polyurethane foam prevents water vapor and moisture from penetrating the panel. This makes them resistant to mold, mildew, and rot—issues that often affect traditional insulation materials. Panels with moisture-resistant facings are ideal for humid climates, cold storage, and food processing facilities.

4. Dimensional Stability

Polyurethane panels maintain their shape and insulation performance over time. They are less susceptible to settling, shrinking, or sagging than loose-fill or batt insulation, which ensures long-term reliability and consistent energy savings.

5. Fire Retardancy and Safety

Most polyurethane insulation panels are formulated with fire-retardant additives and comply with fire resistance standards. Some panels can also be used in fire-rated assemblies when installed with proper cladding and fire barriers.

6. Versatile Applications

Thanks to their customizable dimensions and finishes, polyurethane panels are used in a wide array of settings—from residential homes to refrigerated trucks to industrial buildings. They can be adapted for interior and exterior use, curved surfaces, or modular units.

Common Applications of Polyurethane Insulation Panels

1. Commercial and Industrial Buildings

Used extensively in warehouses, factories, and commercial structures, these panels provide excellent insulation for walls, roofs, and partitioning systems. Their quick installation and energy efficiency help reduce heating and cooling costs in large-volume spaces.

2. Cold Storage and Refrigeration

Due to their high insulation values, polyurethane panels are the material of choice for walk-in freezers, cold rooms, and refrigerated warehouses. They help maintain low internal temperatures with minimal energy input.

3. Residential Construction

In homes, polyurethane insulation panels can be used in exterior walls, attics, and even floors. Their airtight structure helps create a thermal envelope that minimizes energy loss and improves comfort year-round.

4. Prefab and Modular Buildings

Modular builders favor polyurethane panels for their ease of integration, consistent quality, and reduced construction time. They help accelerate project timelines while delivering high energy performance.

5. Vehicle and Trailer Insulation

Refrigerated trucks, RVs, and mobile workspaces benefit from the lightweight, durable insulation properties of polyurethane panels. These panels reduce vehicle weight and improve thermal regulation during transport.

6. Greenhouses and Agricultural Buildings

In controlled-environment agriculture, maintaining consistent temperatures is critical. Polyurethane panels offer reliable insulation that helps reduce heating and cooling requirements in barns, greenhouses, and animal enclosures.

Environmental and Energy Benefits

1. Reduced Carbon Footprint

The superior insulation of polyurethane insulation panels helps reduce energy consumption for heating and cooling. This leads to lower carbon emissions from buildings and vehicles, contributing to a more sustainable operation.

2. Long Lifecycle Performance

Because polyurethane panels are highly durable and resistant to degradation, they rarely need replacement. This long lifespan minimizes material waste and reduces the environmental burden of frequent renovations or maintenance.

3. Compatibility with Green Building Standards

Many polyurethane panels contribute to green building certifications like LEED or BREEAM by improving thermal performance, airtightness, and overall building efficiency.

Design Considerations and Limitations

While polyurethane insulation panels offer many benefits, there are a few considerations to keep in mind:

-

Cost: They are generally more expensive per square foot than fiberglass or mineral wool insulation. However, their higher performance often justifies the initial investment through long-term energy savings.

-

Fire Ratings: Not all polyurethane panels are fire-rated. For applications requiring specific fire safety standards, ensure the panels meet local building codes and include protective layers as needed.

-

UV Sensitivity: Exposed polyurethane surfaces can degrade under UV light. For outdoor applications, panels must be covered or coated with UV-resistant materials.

-

Environmental Impact of Production: Traditional polyurethane foam uses blowing agents that can have a high global warming potential (GWP). Manufacturers are increasingly switching to low-GWP options, but it’s important to verify product sustainability certifications when sourcing materials.

Tips for Installing Polyurethane Insulation Panels

-

Use Compatible Sealants: To ensure airtightness, use sealants and adhesives that are chemically compatible with polyurethane foam and panel facings.

-

Avoid Compression: Over-compressing the panels during installation can damage the foam core and reduce insulation performance.

-

Protect Edges: Use edge trims or barriers to protect the foam core from mechanical damage and moisture intrusion.

-

Proper Fastening: Follow manufacturer guidelines for screw placement and spacing to avoid panel bowing or detachment under load.

Conclusion

Polyurethane insulation panels are a modern, high-performance solution for achieving exceptional thermal insulation in buildings, vehicles, and industrial enclosures. Their unmatched combination of high R-values, moisture resistance, structural integrity, and versatility make them a preferred choice in applications demanding energy efficiency and long-term reliability.

Whether you are designing a residential home, constructing a cold storage facility, or building an energy-efficient prefab unit, polyurethane panels provide the performance you need to meet the demands of today’s energy-conscious world.

-